|

State of Florida

|

Public Service Commission

Capital Circle Office Center ● 2540 Shumard

Oak Boulevard

Tallahassee, Florida 32399-0850

-M-E-M-O-R-A-N-D-U-M-

|

|

DATE:

|

November 22, 2016

|

|

TO:

|

Office of Commission Clerk (Stauffer)

|

|

FROM:

|

Office of the General Counsel (Harper)

Division of Economics

(Rome)

Division of Engineering

(Matthews, Moses)

|

|

RE:

|

Docket No. 160121-GU – Proposed adoption of

Rules 25-6.0346, 25-12.005, 25-12.008, 25-12.022, 25-12.027, 25-12.040, and

25-12.085, F.A.C.

|

|

AGENDA:

|

12/06/16 – Regular Agenda – Interested Persons May Participate

|

|

COMMISSIONERS ASSIGNED:

|

All Commissioners

|

|

PREHEARING OFFICER:

|

Brisé

|

|

RULE STATUS:

|

Proposal May Be Deferred

|

|

SPECIAL INSTRUCTIONS:

|

None

|

|

|

|

|

Case Background

Rules 25-6.0346,

Quarterly Reports of Work Orders and Safety Compliance, 25-12.005, Codes and

Standards Adopted, 25-12.008, New, Reconstructed or Converted Facilities,

25-12.022, Requirements for Distribution System Valves, 25-12.027, Welder Qualification,

25-12.040, Leak Surveys, Procedures and Classification, and 25-12.085, Written

Annual Reports Required, Florida Administrative Code (F.A.C.), implement

federal and state gas and electric safety rules. The purpose of this rulemaking is to update,

clarify, and streamline the Commission rules.

The rules implement Sections 366.04(2)(f)(6), 368.05(1) and (2), 368.03,

and 368.05, Florida Statutes, (F.S.).

The Commission’s

Notice of Development of Rulemaking was published in the Florida Administrative

Register (F.A.R.), on April 20, 2016, in Volume 42, Number 77. Comments were received from Tampa Electric

Company (TECO), Florida Natural Gas Association, and Florida Electric Cooperatives

Association. No rulemaking workshop was

requested, and no workshop was held.

This

recommendation addresses whether the Commission should approve staff’s proposed

amendments of electric and gas safety Rules 25-6.0346, 25-12.005, 25-12.008,

25-12.022, 25-12.027, 25-12.040, and 25-12.085, F.A.C. The Commission has jurisdiction pursuant to

Sections 120.54 and 366.06(1), F.S.

Discussion

of Issues

Issue 1:

Should the Commission propose the amendment of Rules

25-6.0346, 25-12.005, 25-12.008, 25-12.022, 25-12.027, 25-12.040, and 25-12.085,

F.A.C.?

Recommendation:

Yes. The

Commission should propose the amendment of Rules 25-6.0346, 25-12.005,

25-12.008, 25-12.022, 25-12.027, 25-12.040, and 25-12.085, F.A.C., as set forth

in Attachment A. (Harper, Matthews, Moses, Rome)

Staff Analysis:

The purpose of this rulemaking is to update,

clarify, and streamline the Commission gas and electric safety rules. Staff is recommending that the Commission

propose the amendment of the rules, as set forth in Attachment A. Below is a more detailed explanation of the

rule amendments staff is recommending.

Electric Utilities

Rule 25-6.0346,

F.A.C., Quarterly Reports of Work Orders and Safety Compliance

Rule 25-6.0436, F.A.C., specifies that required quarterly work order lists

be sent directly to Commission staff via e-mail, without requiring a specific

form that must be used, as long as there is sufficient information provided.

Proposed language has been added to the rule to clarify the types of

information required to be provided including utility name, contact name,

quarter and year, work order number, location of construction, county of construction,

estimated costs and a brief description of the work. The recommended revisions

to the rule also include a hyperlink to an existing Commission form which can

be used as an example format that would meet the reporting requirements of the

rule.

Gas Utilities

Rule 25-12.005, Codes and Standards Adopted

Rule 25-12.005, F.A.C. implements the Minimum Federal

Safety Standards and reporting requirements for pipeline facilities and

transportation of gas as prescribed by Pipeline and Hazardous Materials Safety

Administration (PHMSA) found in 49 C.F.R. Parts 191, 192, and 199. Rule 25-12.005, F.A.C., is amended

to adopt the

latest version of the federal standards 49 C.F.R. Parts 191, 192, and 199 that pertain to reporting

requirements, safety standards, and drug and alcohol employee reporting

standards and requirements for employees of gas pipeline operators and

emergency response persons under the direct authority or control of a gas

utility or gas pipeline operator.

Rule 25-12.008, New, Reconstructed or Converted

Facilities

Rule 25-12.008, F.A.C., pertains to inspection of new, reconstructed, or

converted pipeline facilities. Rule 25-12.008, F.A.C., is amended to adopt the latest version of 49 C.F.R. Part 192 and to

clarify that there is no requirement of visual inspection of underground

facilities if construction and testing records have been maintained, and to

clarify that active corrosion procedures are required by Subpart I of 49 C.F.R.

Part 192.

Rule 25-12.022, Requirements for Distribution System

Valves

Rule 25-12.022, F.A.C., provides the requirements for gas

distribution system valves. Staff

recommends amendments to Rule 25-12.022, F.A.C., to include

the use of the word “emergency” in conjunction with the word “sectionalizing”

in subsections (3) and (5) of the rule. The intent of the recommended amendments

is to clarify those valves used to close off system sections in an emergency.

Additional modifications to Rule 25-12.022, F.A.C. are recommended in paragraph

(3)(b), which would provide clarification that valve identification must be

marked on permanent material inside the valve box.

Rule 25-12.027, Welder Qualification

Rule 25-12.027, F.A.C., provides the standards for welder qualification.

The amendments to Rule 25-12.027, F.A.C., would correct a scrivener’s error in

the current rule and clarify the appropriate American Petroleum Institute

standards for welder qualification. The rule also would be updated to adopt the

latest version of the federal standard 49 C.F.R. Part 192 as it pertains to

welder qualification.

Rule 25-12.040, Leak Surveys, Procedures and

Classification

Rule 25-12.040, F.A.C., provides the requirements for gas leak surveys,

procedures, and classification. The amendments to Rule 25-12.040(1)(b), F.A.C.,

would provide clarification regarding the intervals within which leak detection

surveys are required. Staff recommends additional amendments to Rule 25-12.040,

F.A.C., include new subsection (4). Under current Commission rules,

gas utilities are required to perform follow-up inspections of leak repairs no

later than one month for Grade 1 leaks and no later than six months for Grade 2

leaks. New language included in subsection (4) would require that if residual

gas is detected on the follow-up inspection, continued monthly monitoring and

inspections shall be done until gas is no longer detected.

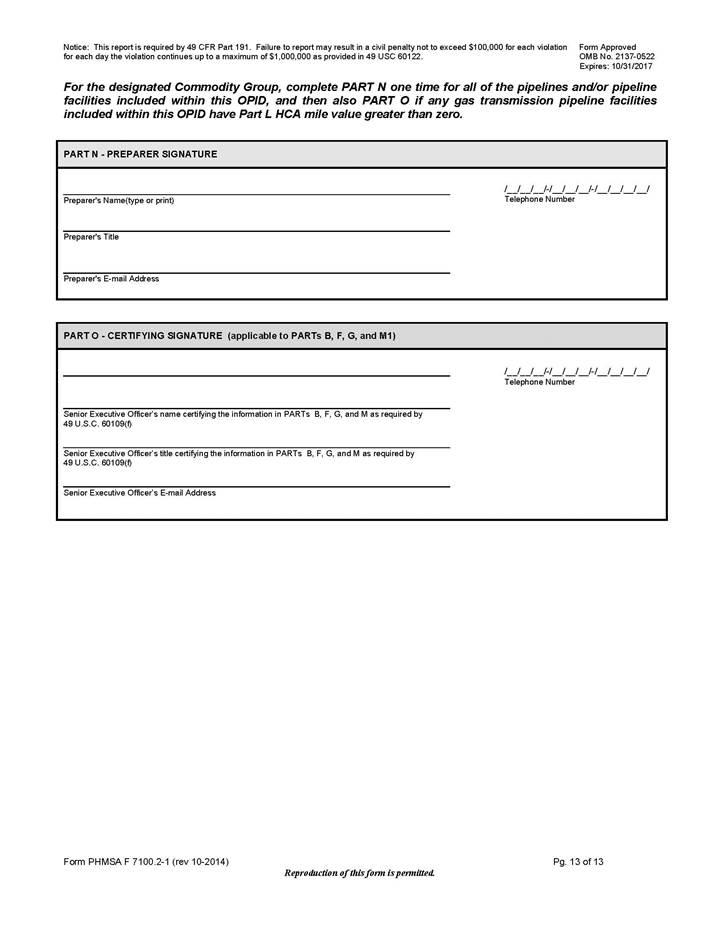

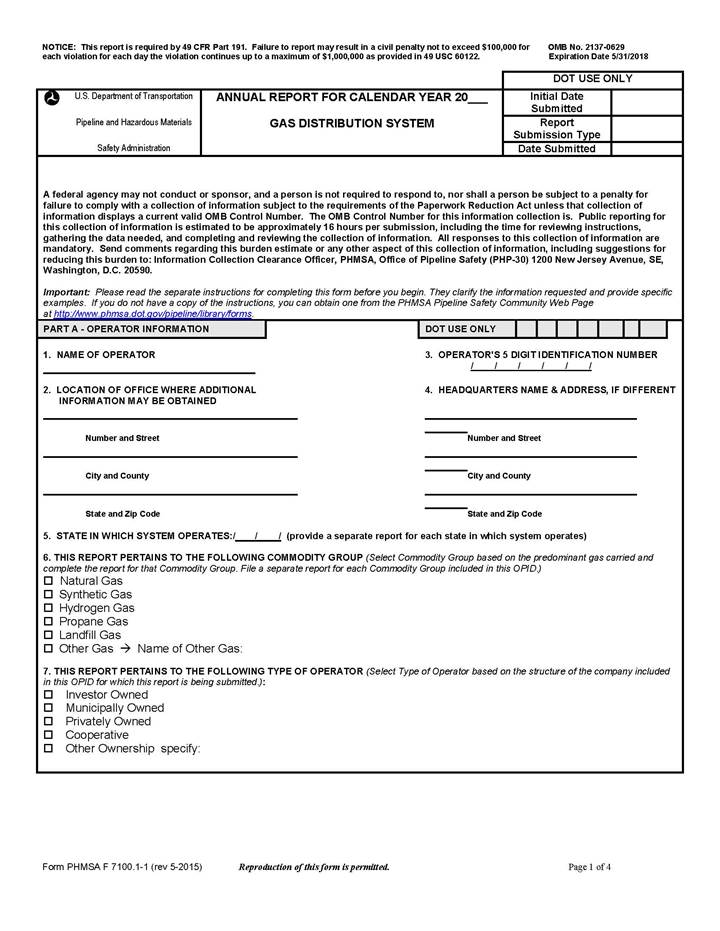

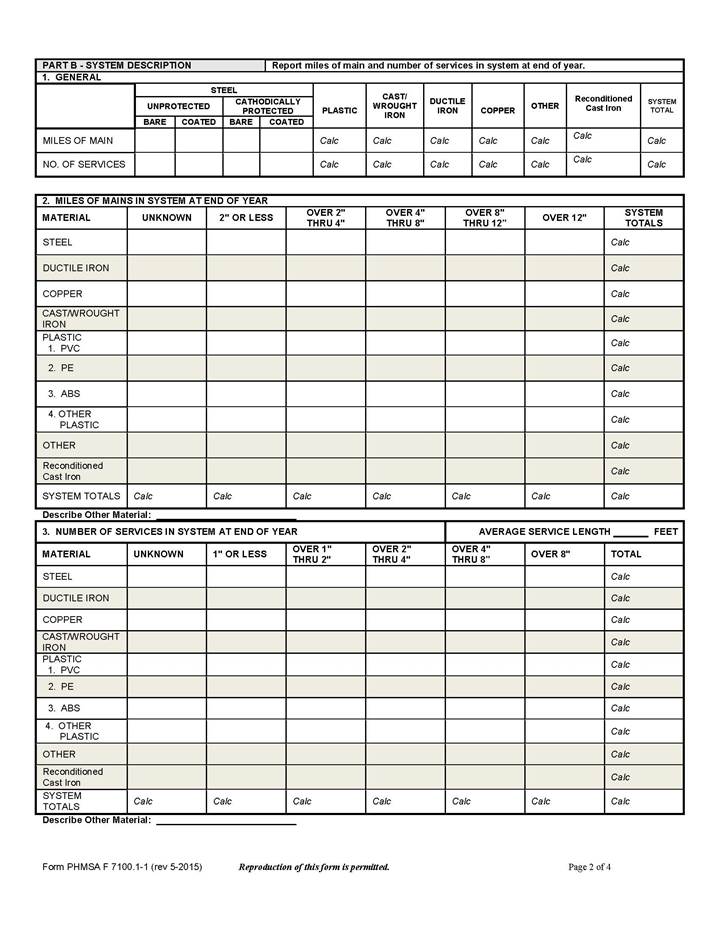

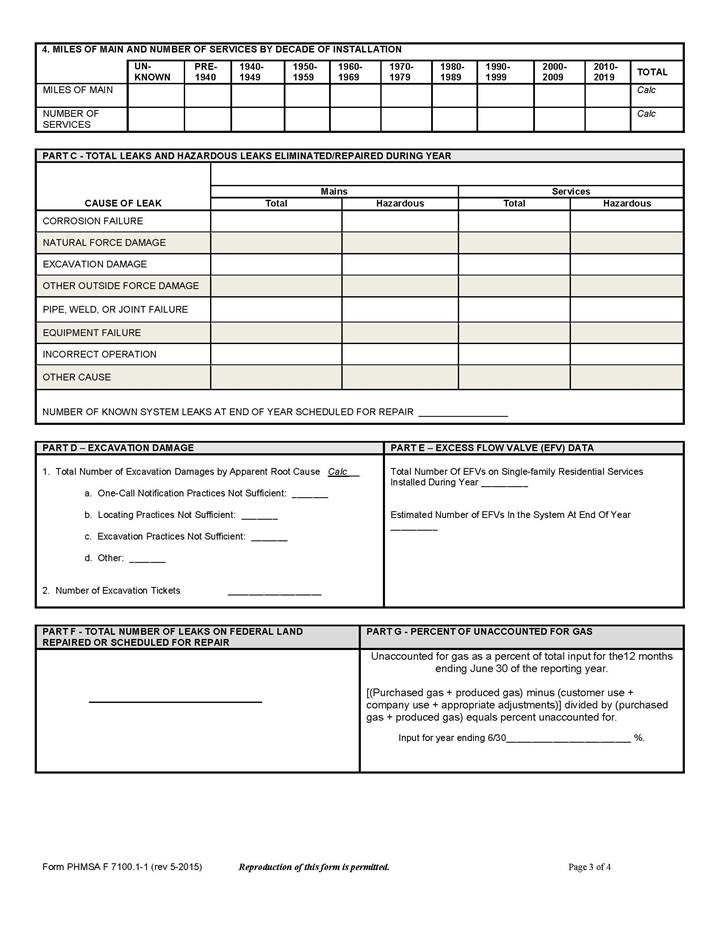

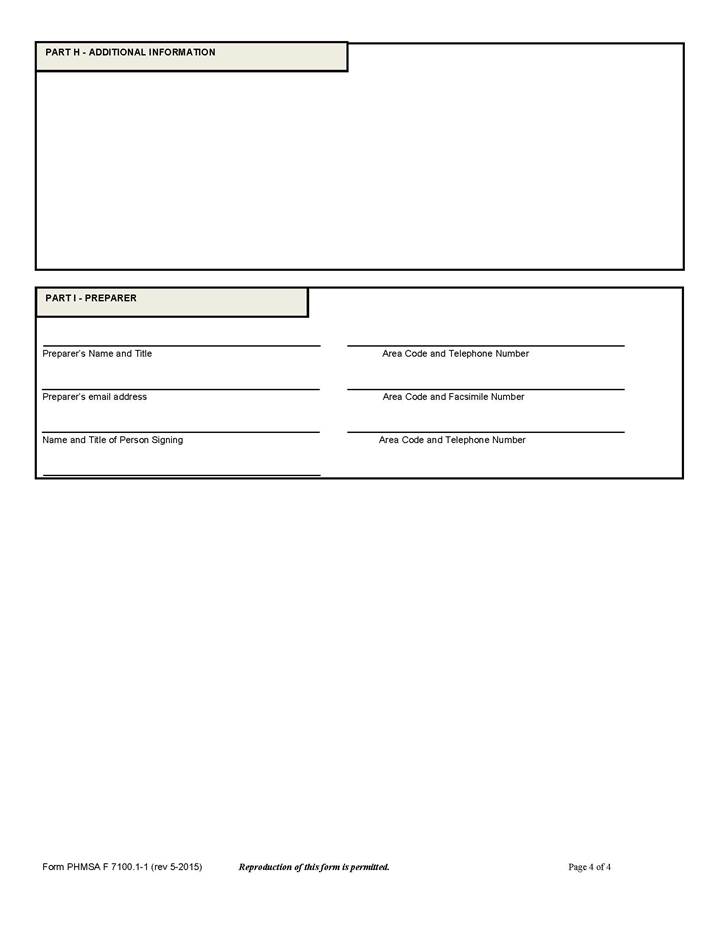

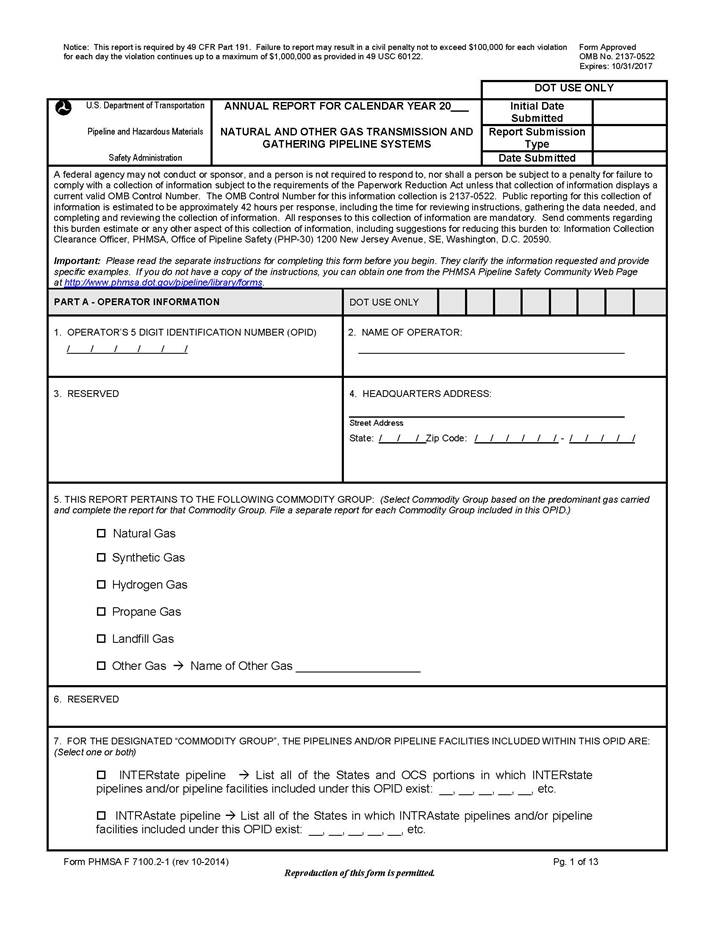

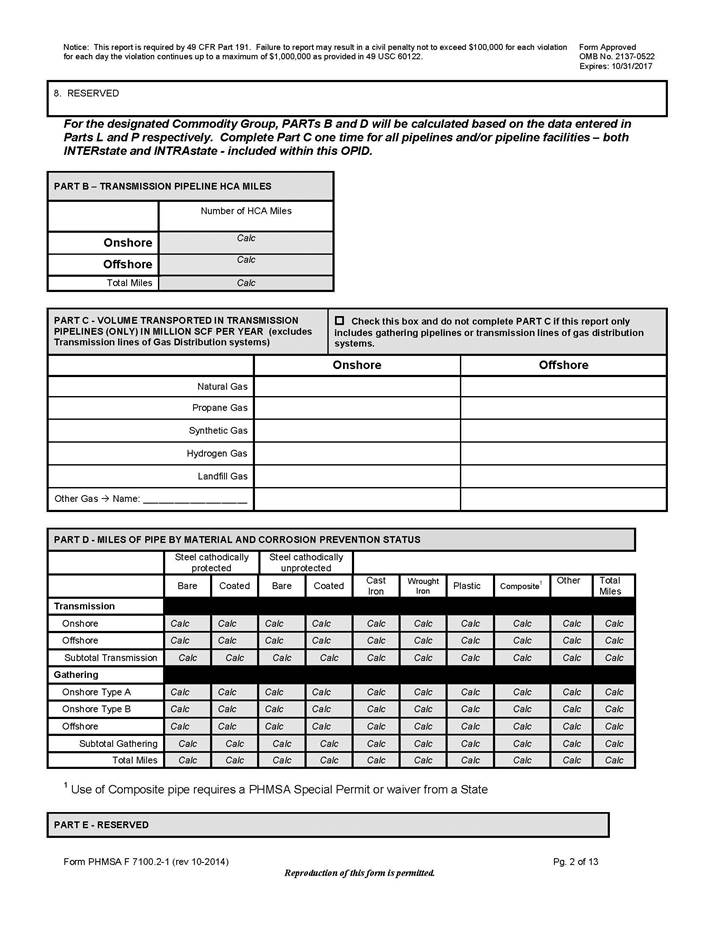

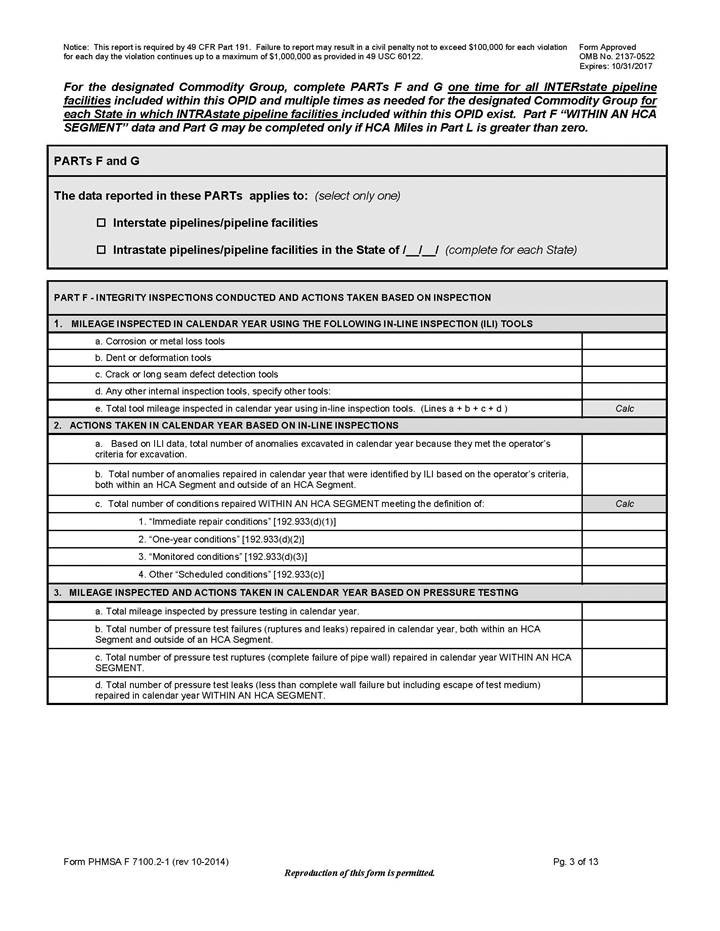

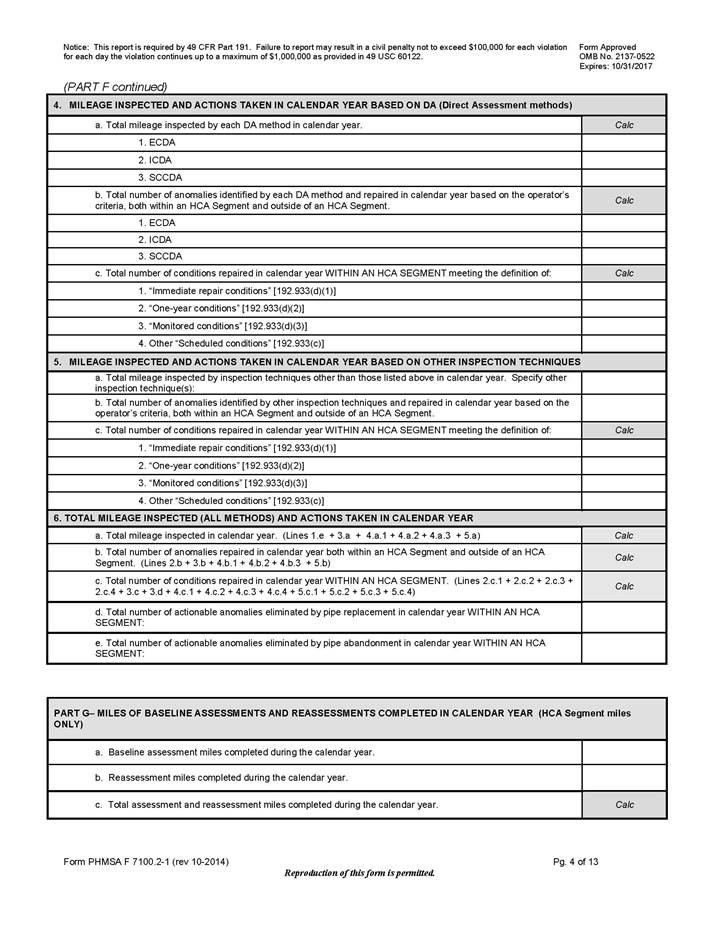

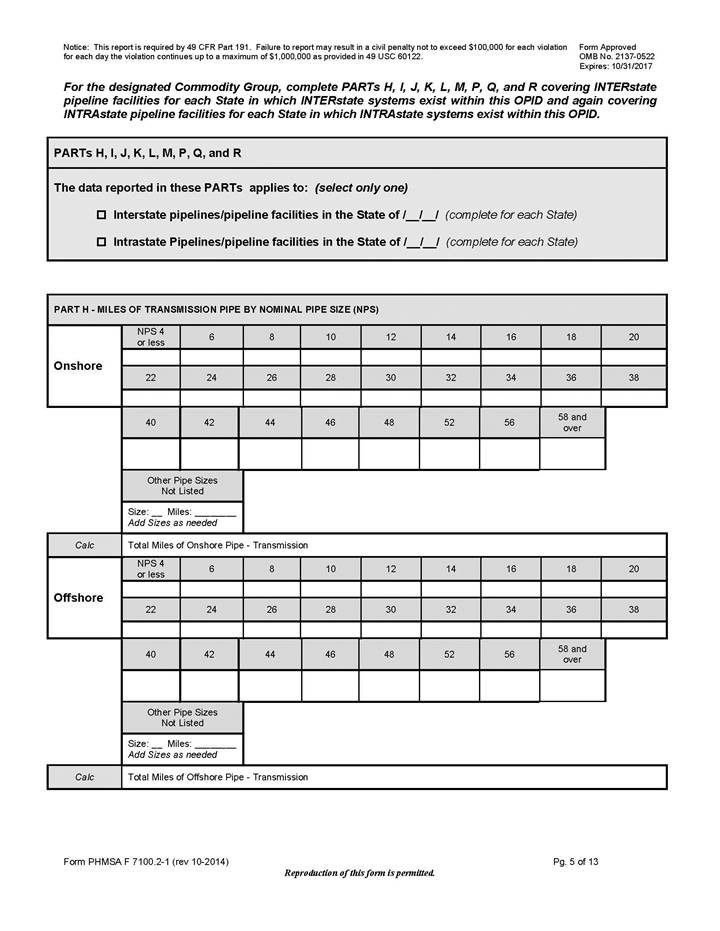

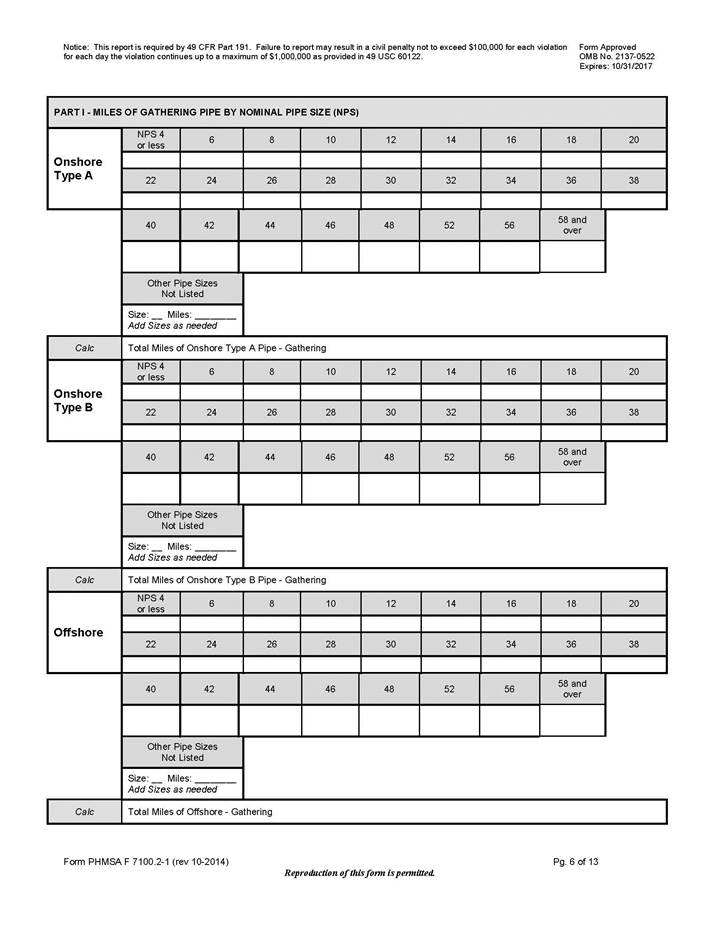

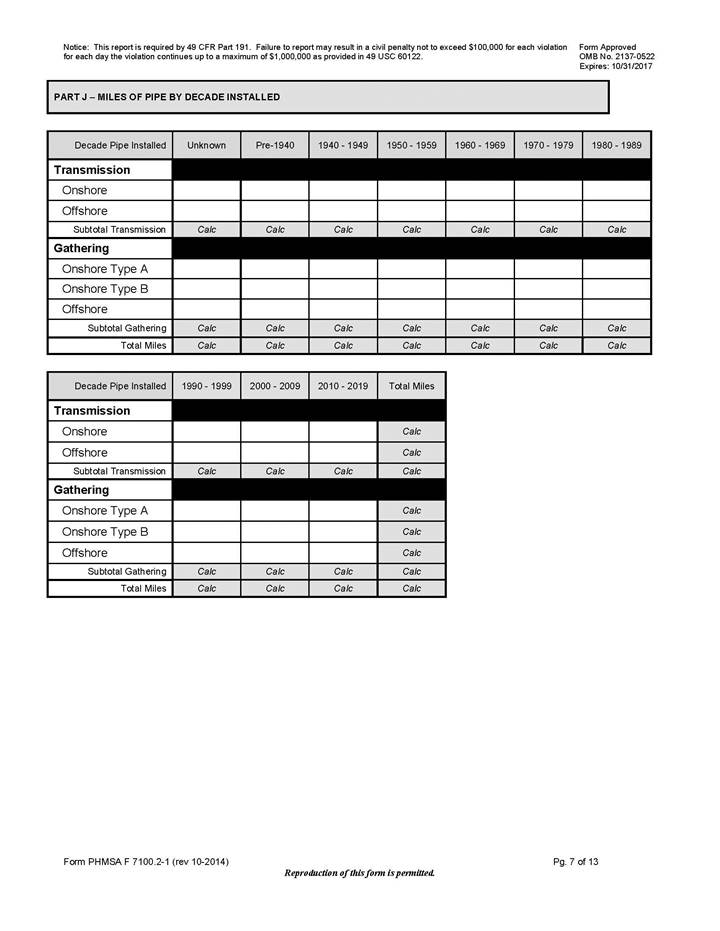

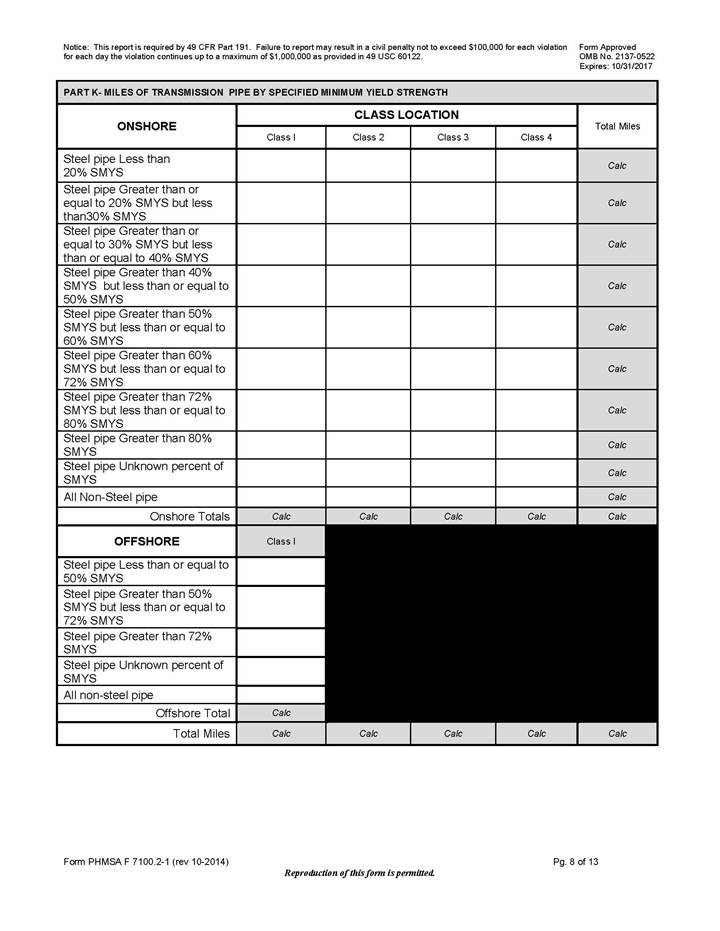

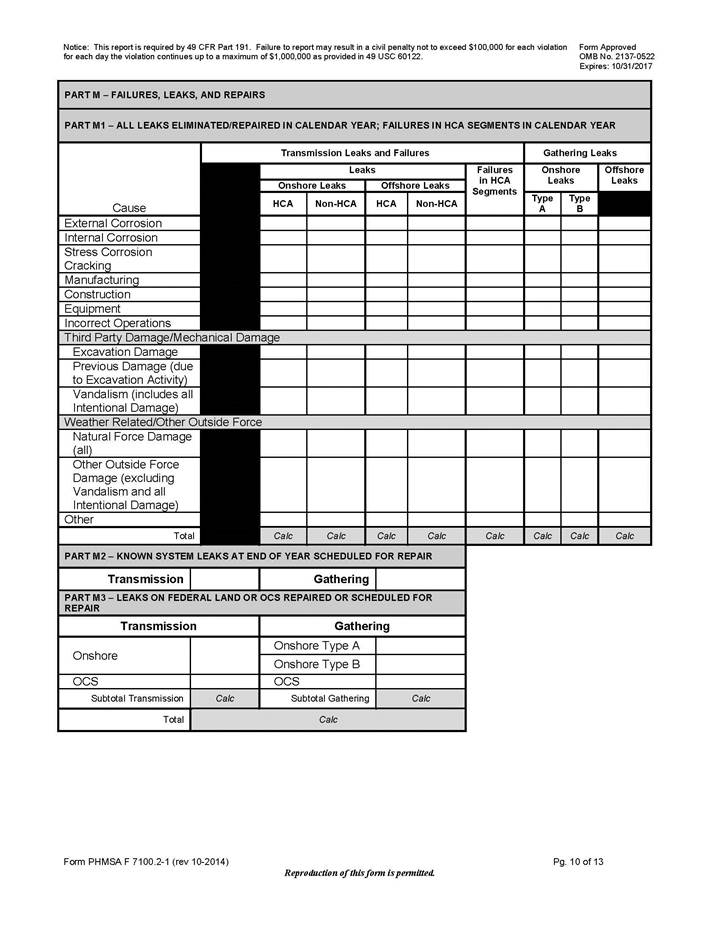

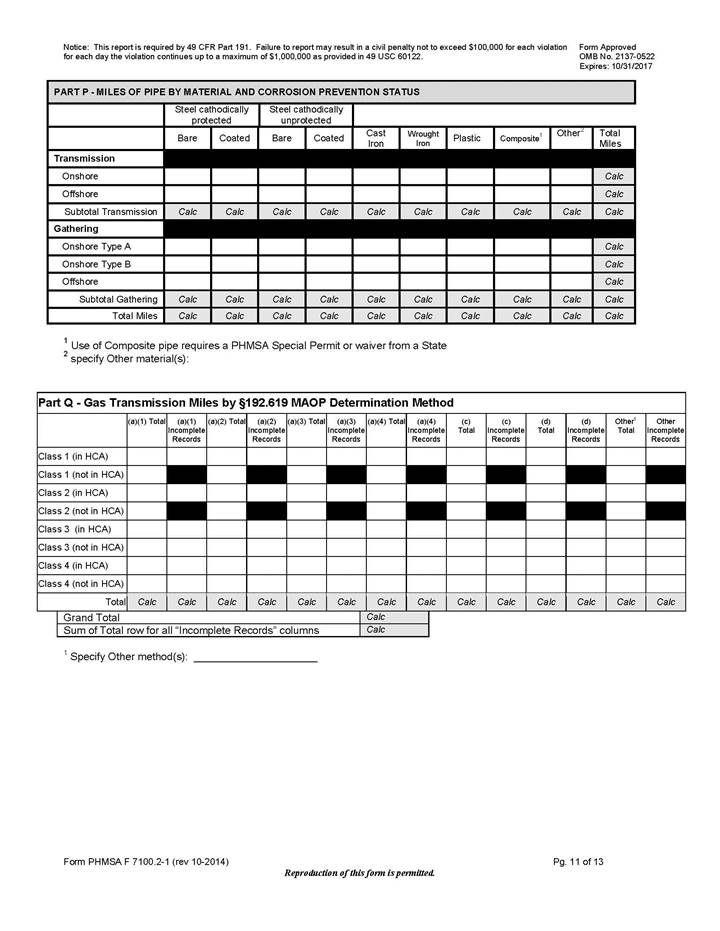

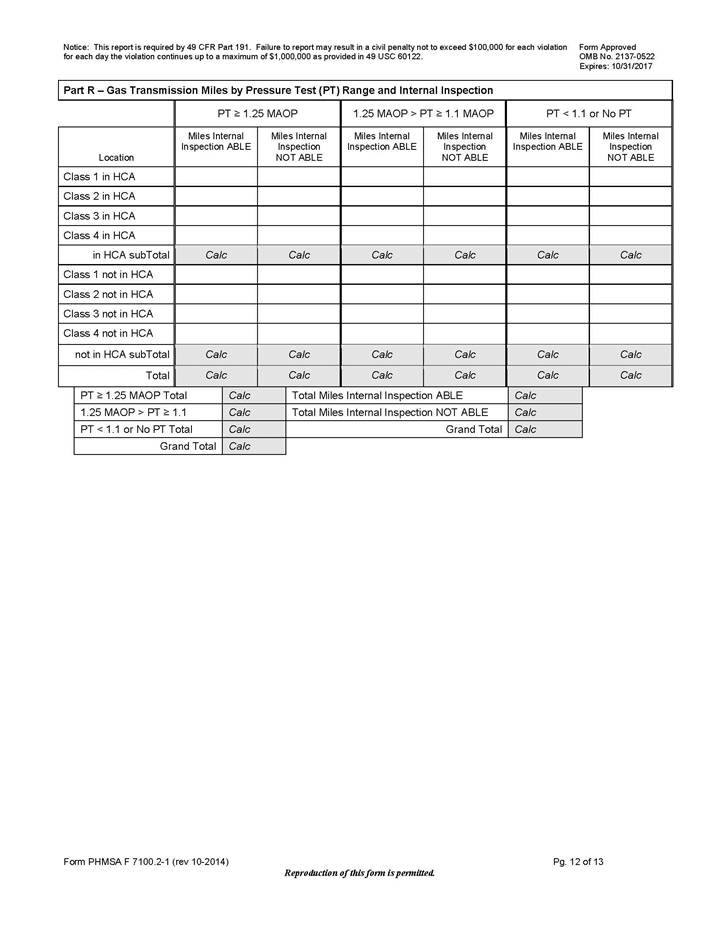

Rule 25-12.085, Written Annual Reports Required

Rule 25-12.085, F.A.C., provides the requirement for annual written

reports by gas distribution operators pursuant to PHMSA Forms 7100.1-1 and

7100.2-1. The recommended amendments to

subsections (1) and (3) of Rule 25-12.085, F.A.C., would incorporate the most

recent versions of the appropriate PHMSA forms. The most recent versions of the

forms are included in Attachment A for reference. Subsection (2) of Rule

25-12.085, F.A.C., is recommended for deletion as redundant.

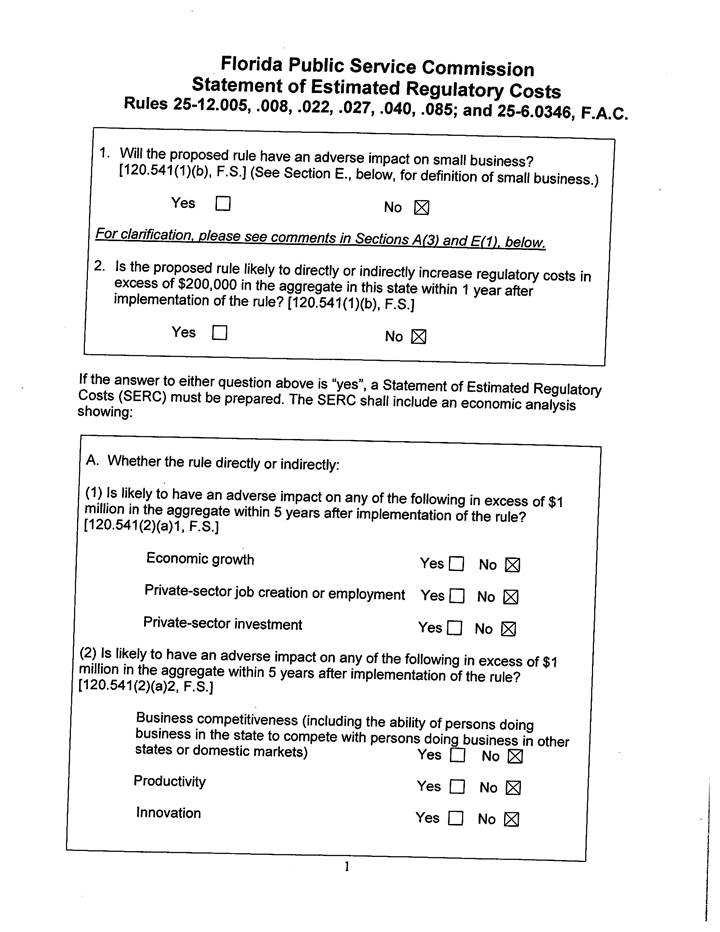

Statement of Estimated Regulatory Costs

Pursuant to Section 120.54, F.S., agencies are encouraged

to prepare a statement of estimated regulatory costs (SERC) before the

adoption, amendment, or repeal of any rule.

The SERC is appended as Attachment B to this recommendation. The SERC analysis also includes whether the

rule amendment is likely to have an adverse impact on growth, private sector

job creation or employment, or private sector investment in excess of $1

million in the aggregate within five years after implementation.

The SERC concludes that the rule amendments will not

likely directly or indirectly increase regulatory costs in excess of $200,000

in the aggregate in Florida within one year after implementation. Further, the

SERC concludes that the rule amendments will not likely have an adverse impact

on economic growth, private-sector job creation or employment, private sector

investment, business competitiveness, productivity, or innovation in excess of

$1 million in the aggregate within five years of implementation. Thus, the rule amendments do not require

legislative ratification pursuant to Section 120.541(3), F.S.

In addition, the SERC states that the rule amendments will

not have an adverse impact on small business and will have no impact on small

cities or small counties. No regulatory

alternatives were submitted pursuant to paragraph 120.541(1)(a), F.S. None of the impact/cost criteria established

in paragraph 120.541(2)(a), F.S., will be exceeded as a result of the

recommended revisions.

Conclusion

Based on the foregoing, staff recommends the amendment of

Rules 25-6.0346, 25-12.005, 25-12.008, 25-12.022, 25-12.027, 25-12.040, and

25-12.085, F.A.C.

Issue 2:

Should this docket be closed?

Recommendation:

Yes. If no

requests for hearing or comments are filed, the rules may be filed with the

Department of State, and this docket should be closed. (Harper, Matthews,

Moses, Rome)

Staff Analysis:

If no requests for hearing or comments are filed,

the rules may be filed with the Department of State, and this docket should be

closed.

25-6.0346 Quarterly Reports of Work Orders

and Safety Compliance.

(1)

Each investor-owned electric utility, rural electric cooperative and municipal

electric utility shall provide a work order list report all completed

electric work orders, relating to the construction and/or maintenance of

transmission and distribution facilities, whether that is completed

by the utility or one of its contractors, at the end of each quarter of the

year. The report work order list shall contain the utility name,

contact name, quarter and year, work order number, location of construction,

county of construction, estimated costs, and brief description of the work

(overhead and underground), and shall be sent via e-mail to electronically

filed with the Electric-QTR-Reports@psc.state.fl.us Commission

Clerk no later than the 30th working day after the last day of the

reporting quarter. using Form PSC/ENG 157 (12/12), “PSC Quarterly

Report of Completed Work Orders,” which is available at http://www.flrules.org/Gateway/reference.asp?No=Ref-02040,. is an example work order list that may

be completed and filed to meet the reporting requirement for this rule. This

form is incorporated into this rule by reference and may also be obtained from

the Commission’s Division of Administrative and Information Technology

Services.

(2)

In its quarterly report, each utility shall certify to the Commission that all

work described in the completed work orders listed in the quarterly report

meets or exceeds the applicable standards. Compliance inspections by the

Commission shall be made on a random basis or as appropriate.

Rulemaking

Authority 350.127(2), 366.05(1) FS. Law Implemented 366.04(2)(f), (6), 366.05(1)

FS. History–New 12-16-12, Amended,____________.

25-12.005 Codes and Standards Adopted.

The Minimum Federal Safety Standards and

reporting requirements for pipeline facilities and transportation of gas

prescribed by the Pipeline and Hazardous Materials Safety Administration in 49

C.F.R. 191 and 192 (2016) (2011), are adopted and incorporated by

reference as part of these rules. 49 C.F.R. 191 (2016) (2011) may

be accessed at [Dept. of State hyperlink] http://www.flrules.org/Gateway/reference.asp?No=Ref-01534.

49 C.F.R. 192 (2016) (2011) may be accessed at [Dept. of State

hyperlink] http://www.flrules.org/Gateway/reference.asp?No=Ref-01535.

49 C.F.R. 199 (2016) (2011), “Drug and Alcohol Testing,” is

adopted and incorporated by reference to control drug use, by setting standards

and requirements to apply to the testing and use of all emergency response

personnel under the direct authority or control of a gas utility or pipeline

operator, as well as all employees directly or indirectly employed by gas

pipeline operators for the purpose of operation and maintenance and all

employees directly or indirectly employed by intrastate gas distribution

utilities for on-site construction of natural gas transporting pipeline

facilities 49 C.F.R. 199 (2016) (2011) may be accessed at [Dept.

of State hyperlink] http://www.flrules.org/Gateway/reference.asp?No=Ref-01537.

Part 199 also is adopted to prescribe standards for use of employees who do not

meet the requirements of the regulations.

Rulemaking

Authority 368.03, 368.05(2), 350.127(2) FS. Law Implemented 368.03, 368.05 FS.

History–New 11-14-70, Amended 9-24-71, 9-21-74, 10-7-75, 11-30-82, 10-2-84,

Formerly 25-12.05, Amended 8-8-89, 1-7-92, 5-13-99, 4-26-01, 12-15-09, 10-11-12,_________.

25-12.008 New, Reconstructed or Converted Facilities.

(1)

No new or reconstructed system or portion thereof may be:

(a)

Constructed, until written construction specifications complying with these

rules are developed.

(b)

Placed in service until the pipeline facilities have been inspected and found

to comply with the construction specifications and Operating and Maintenance

Plans.

(2)

Before a piping system can be converted to a regulated gas, the operator must:

(a)

Have a general conversion procedure as a part of its operation and maintenance

plan.

(b)

File a conversion plan with the Commission for the specific system at least 15

days prior to start of conversion. This plan need not be filed for minor

conversions which are scheduled to be completed in one day and where

sectionalizing of the system to be converted is not planned.

(c)

Have sufficient inspections performed of the pipeline to assure that it

was constructed in accordance with standards applicable at the time of

installation. Visual inspection of the underground facilities may will

not be required if adequate construction and testing records have been

maintained.

(d)

Review the operating and maintenance history of the system to be converted. Any

areas showing abnormal maintenance requirements shall be replaced,

reconditioned or otherwise made safe prior to conversion.

(e)

Establish the maximum allowable operating pressure no greater than the highest

sustained operating pressure during the 5 years prior to conversion unless it

was tested or uprated after July 1, 1970 in accordance with the Subparts J or K

of 49 C.F.R. 192 (2016) (2011) as adopted in Rule 25-12.005,

F.A.C.

(f)

Make a leak survey over the entire converted system concurrent with the

conversion.

(g)

Determine areas of active corrosion as required by Subpart I of 49

C.F.R. 192 (2016) (2011) and these rules. Required cathodic

protection must be accomplished within 1 year after the date of conversion

except that buried steel tubing must be protected prior to placing the system

into operation.

Rulemaking

Authority 350.127(2), 368.03, 368.05(2) FS. Law Implemented 368.03, 368.05(2)

FS. History–New 11-14-70, Amended 9-21-74, 10-7-75, 10-2-84, Formerly 25-12.08,

Amended 12-15-09, 10-11-12, ___________.

25-12.022 Requirements for Distribution System Valves.

(1)

Valves ahead of regulator stations – A valve shall be installed upstream of

each regulator station for use in an emergency to stop the flow of gas. These

valves are to be installed at a safe distance from the station, but no more

than 500 feet from the regulator station. The distance for the valve location

can be greater than 500 feet if physically impractical to install closer.

(2)

Sectionalizing valves – Valves shall be spaced within each distribution system

to reduce the time to shut-down a segment of the system in an emergency. In

determining the spacing of these valves, the following factors shall be

evaluated:

(a)

Volume and pressure of gas between valves.

(b)

Size of area and population density between valves required to isolate the area

and as well as the accessibility of the required valves.

(c)

The minimum number of personnel required to shutdown and restore the area.

(d)

Other means and availability of required equipment to control the flow of gas

in the event of an emergency.

(e)

The number and type of customers, such as hospitals, schools, commercial, and industrial

loads, etc., that will be affected.

(3)

Identification – Emergency or sSectionalizing and other critical

valves shall be designated on appropriate records, drawings or maps used by the

operator and shall be referenced to “permanent” aboveground structures or other

field ties so the valves can be readily located. The centerline of the road or

highway, property line, or right-of-way may be used as one of the referenced

structures. The valve installation and all records showing these valves

must be marked for prompt identification using any logical designating system.

The valve marking must be accomplished using a durable tag or other equivalent

means located as follows:

(a)

For aboveground valves or valves located in vaults which have to be operated

from within the vault, the marking shall appear on the valve body or hand

wheel.

(b)

For buried valves or valves operated by a key wrench, the marking shall be

legible and may be on any type of permanent material placed appear

in a visible location on the inside of the curb box or standpipe where

the cover will not abrade the marking. Marking the cover only is not

acceptable.

(4)

Blowdown valve requirements – Where blowdown valves are used to aid the

evacuation of gas from segments of mains between isolation valves, these valves

must:

(a)

Be protected against tampering and mechanical damage from outside forces.

(b)

Be designed for safe venting giving consideration to the direction of flow,

electric facility locations, proximity of people, etc.

(c)

Be readily accessible in the event of an emergency.

(5)

All the sectionalizing or emergency valves which may be necessary for

the safe operation of the system must be inspected and maintenance performed to

assure location, access and operating ability at intervals not exceeding 15

months but at least each calendar year.

Rulemaking

Authority 368.05(2) FS. Law Implemented 368.05(2) FS. History–New 9-21-74,

Amended 10-7-75, 10-2-84, Formerly 25-12.22, Amended 12-15-09,_________.

25-12.027 Welder Qualification.

(1)

No welder shall make any pipeline weld unless the welder has qualified in

accordance with Section 63, or section 12 for automatic

welding, of American Petroleum Institute Standard 1104, Welding of

Pipelines and Related Facilities, 21st 20th edition, September

2013 October 2005 including Errata/Addendum July 2007 and Errata 2

(2008), incorporated by reference herein, or Appendix C of 49 C.F.R. 192 (2016)

(2011) as adopted in Rule 25-12.005, F.A.C., within the preceding

15 months, but at least once each calendar year. A copy of API 1104 may be

obtained from http://www.api.org/Standards/.

(2)

No welder shall weld with a particular welding process unless the welder has

engaged in welding with that process within the preceding six calendar months.

A welder who has not engaged in welding with that process within the preceding

six calendar months must requalify for that process as set forth in subsection

(1) of this rule herein.

Rulemaking

Authority 350.127(2), 368.03, 368.05(2) FS. Law Implemented 368.03, 368.05 FS.

History–New 1-7-92, Amended 12-15-09, 10-11-12,___________.

25-12.040 Leak Surveys, Procedures and Classification.

(1)

Each operator shall perform periodic leakage surveys in accordance with the

following schedule as a minimum:

(a)

A gas detector instrument survey shall be conducted at intervals not exceeding

15 months but at least once each calendar year in those portions of an

operator’s service area, including:

1.

Principal business districts, master meter systems, and places where the public

is known to congregate frequently.

2.

Where pipeline facilities, including service lines, are located under surfaces

of such construction that little opportunity is afforded for a leak to vent

safely.

(b)

A gas detector instrument survey to locate leaks throughout areas not included

in subsection (a) above shall be conducted at intervals not exceeding three

(3) calendar years at intervals not exceeding 39 months

on bare metallic, galvanized steel, coated tubing pipelines, and five (5)

calendar years at intervals not exceeding 63 months on the

remaining pipeline system, or more frequently if experience indicates.

(2)

The following leak classification system shall be used on all leak records and

reports:

(a)

“Grade 1 Leak” – a leak of gas that represents an existing or probable hazard to

persons or buildings. In order Prompt action to protect life and

property, these leaks shall be repaired immediately and continuous

action shall be taken until conditions are no longer hazardous is

required.

(b)

“Grade 2 Leak” – a leak that is not a threat to persons or property at the time

of detection, but justifies scheduled repair based on potential future hazard.

These leaks shall be repaired within 90 days from the date the leak was

originally located, unless due to resurvey the leak was determined to be Grade

3 as defined in subsection (c) below. In determining the time period for

repair, the following criteria should be taken into consideration:

1.

Amount and migration of gas;

2.

Proximity of gas to buildings and subsurface structures;

3.

Extent of pavement;

4.

Soil type and conditions, such as moisture and natural venting.

(c)

“Grade 3 Leak” – a leak that is not a threat to persons and property and is not

expected to become so. Above ground grade 3 leaks shall be repaired within 90

days from the date the leak was originally located unless the leak is upgraded

or does not produce a positive leak indication when a soap and water solution,

or its equivalent, is applied on suspected locations at operating pressure.

Grade 3 leaks that are underground shall be reevaluated at least once every 6

months until repaired. The frequency of reevaluation shall be determined by the

location and magnitude of the leak.

(3)

The adequacy of Aall the repairs of leaks shall be checked

by appropriate methods immediately after the repairs are completed. Where there

is residual gas in the ground, a follow-up inspection using a gas detector

instrument must be made as soon as the gas has had an opportunity to dissipate,

but no later than one month for Grade 1 leaks and 6 months for Grade 2 leaks.

The date and status of recheck shall be recorded on the leak repair records.

(4)

If residual gas is detected on the follow-up inspection, continued monthly

monitoring, not to exceed 45 days, and inspections shall be done until gas is

no longer detected.

Rulemaking

Authority 368.05(2) FS. Law Implemented 368.05(2) FS. History–New 9-21-74,

Repromulgated 10-7-75, Amended 10-2-84, Formerly 25-12.40, Amended 1-7-92,

12-15-09, _________.

25-12.085 Written Annual Reports Required.

(1)

Each operator of a distribution system shall submit an annual report on

Pipeline and Hazardous Materials Safety Administration Form PHMSA F 7100.1-1 (2015)

(12-05), entitled “Annual Report for Calendar Year 20____ Gas

Distribution System,” which is

incorporated by reference into this rule and is available at [Department

of State hyperlink] for each distribution system. In the case of an

operator who has more than one distribution system, a combined annual report

must be submitted which includes all facilities operated within the State of

Florida subject to the Commission’s jurisdiction.

(2)

Each operator of a distribution system shall, for facilities that operate at 20

percent or more of the specified minimum yield strength, or that are used to

convey gas into or out of storage, submit an annual reports for those

facilities on Pipeline and Hazardous Materials Safety Administration Form PHMSA

F 7100.2-1 (12-05), entitled “Annual Report for Calendar Year 20____ Gas

Transmission & Gathering Systems.”

(2)(3)

Each operator of a transmission system shall submit an annual report on

Pipeline and Hazardous Materials Safety Administration Form PHMSA F 7100.2-1 (2014)

(12-05), entitled “Annual Report for Calendar Year 20__ Natural and Other Gas Transmission and

Gathering Pipeline Systems,” which

is incorporated by reference into this rule and is available at [Department

of State hyperlink].

All the above reports must be submitted

for the preceding calendar year so as to be received by the Commission no later

than March 15th of each year.

Rulemaking

Authority 350.127(2), 368.05(2) FS. Law Implemented 368.03, 368.05(2) FS.

History–New 11-14-70, Amended 9-21-74, Repromulgated 10-7-75, Amended 10-2-84,

Formerly 25-12.85, Amended 12-15-09, _________.